Продовольствие

Система качества

-

ISO 9001:2015 / JISQ9001:2015

Сертификация системы менеджмента качества

-

ISO 14001:2015

Сертификация системы мер по охране окружающей среды

-

ISO 45001:2018

Система охраны труда и техники безопасности

-

ISO/IEC 17025:2017 (LAB TAF)

Сертификация TAF (Taiwan Accreditation Foundation – Тайваньский Аккредитационный фонд) комплексного оборудования и компетенции внутрифирменной лаборатории

-

RoHS Compliant

We do not intentionally use any hazardous material required by “RoHS2 EU Directive 2011/65/EU and RoHS3 EU Directive EU/ 2015/863” within compounding process and any others processes.

-

REACH Compliant

We hereby declare that all products(articles) have been designed and manufactured do not contain SVHC above the threshold value.

Загрузить каталог

Consumers these days are educated more than ever concerning food health and safety regulations, and there is an increase in focus on consumer protection concerning food production equipment and systems, packaging and food contact substances. The Food and Drug Administration (FDA) is responsible for protecting and promoting public health and safety through the control and supervision of food safety, medical, biological products, cosmetics, veterinary drugs, medical devices, and diagnostic products.

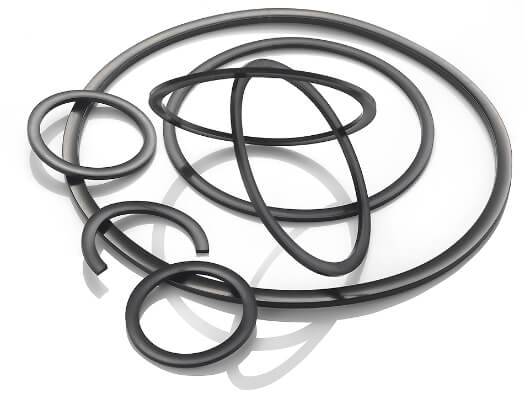

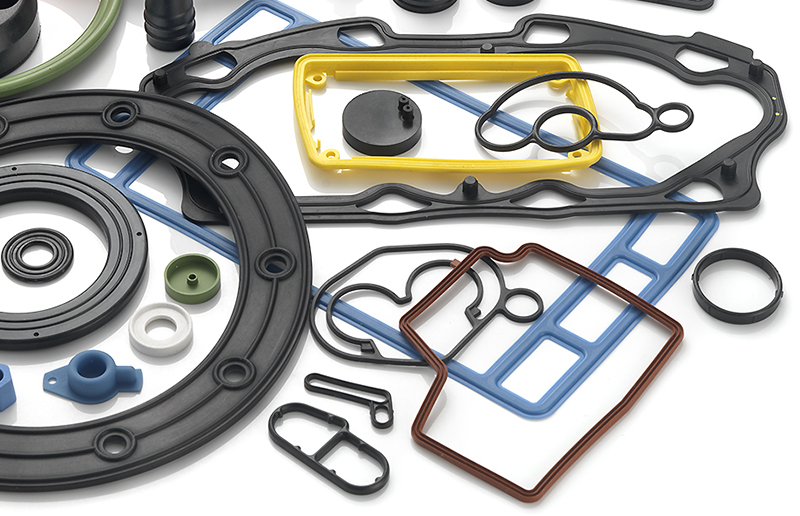

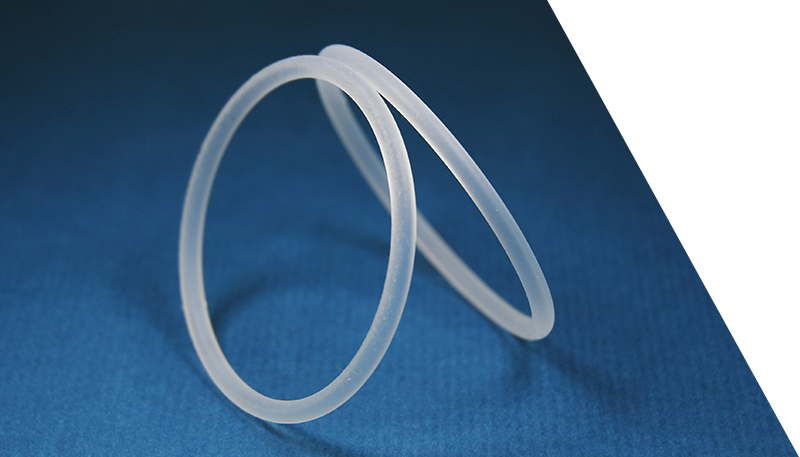

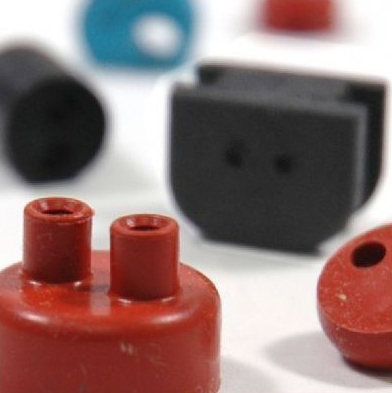

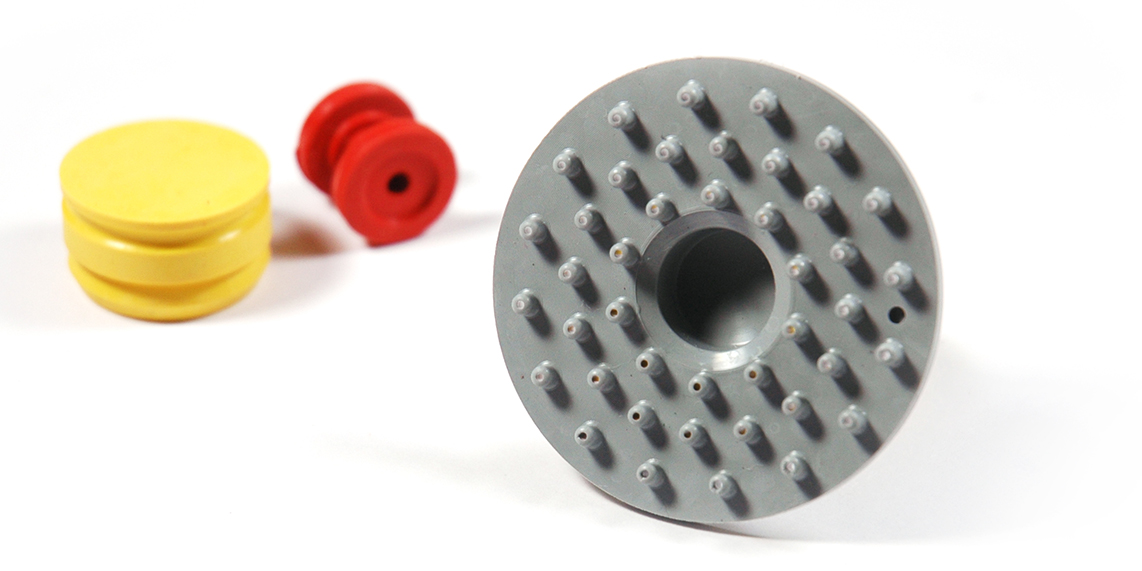

GMORS has decades of experience in producing high quality elastomer parts and products, and we have developed a range of food grade sealing components with excellent mechanical properties and chemical resistance to a broad range of chemical media, including grease, oils, high pressure steam, alcohols, acids and alkalies.

Food grade seals are an integral part of equipment used in food processing, and they are often required to withstand the demanding conditions of equipment cleaning and sterilization under high temperature conditions in the presence of aggressive chemical media.

Our food grade compounds are compliant with the requirements of the Food and Drug Administration (FDA), United States Pharmacopeia (USP Class VI)(V7092AP、9082E), 3A 18-03 Sanitary Standards (3A), and EC Regulation 1935/2004 and 2023/2006 (see the table below). They are suitable for food machinery or food contact equipment. GMORS laboratories can also issue declarations of compliance with U.S. FDA 21 CFR 177.2600 and provide Taiwan SGS extraction test reports.

Additionally, GMORS has the capability of conducting tests on the chemical compatibility profile for every of our certified or compliant compound in our own laboratory, and we do this in accordance with the specifications from our customers.

Public health, safety and efficacy is of utmost importance in the production of food and beverage, and GMORS is your trusted and reliable partner with more than 38 years of experience in the design and manufacturing ofFDA food grade o-rings, seals and gaskets.

We work with our customers in the food and beverage industry in the optimization of seal design and development of new seals. We offer the highest cost-effective solutions that comply with the standards of international food grade regulatory authorities. Let GMORS manage all your sealing needs in compliance with health, safety and hygiene regulations, while you focus on your production.

| Compound | Material | Curing system | Hardness (Shore A) | Color | FDA 21 CFR 177.2600 (a)~(d) | Extraction test results FDA 21 CFR 177.2600 (e)~(f) | FDA 3A Sanitary Standards | Intended for use in contact with milk or edible oils | European Food Contact Material EC 1935/2004 | Japan Food Contact Material JFSL 370 | China Food Contact Material GB4806.11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| E6983AA | EPDM | Perox. | 70 | Black | ✓ | ✓ | |||||

| E7051AA | EPDM | Sulf. | 70 | Black | ✓ | ✓ | CLASS III | ✓ | ✓ | ||

| E7083AA | EPDM | Perox. | 70 | Black | ✓ | ✓ | CLASS III | ✓ | |||

| E7141AA | EPDM | Perox. | 70 | Black | ✓ | ✓ | ✓ | ||||

| E7170AA01 | EPDM | Perox. | 70 | Black | ✓ | ✓ | CLASS IV | ✓ | ✓ | ||

| N7001AA | NBR | Sulf. | 70 | Black | ✓ | ✓ | CLASS III | ✓ | |||

| N7002AA | NBR | Sulf. | 70 | Black | ✓ | ✓ | CLASS III | ✓ | ✓ | ||

| N7018AA | NBR | Perox. | 70 | Black | ✓ | ✓ | CLASS II | ✓ | |||

| N7041AA | NBR | Sulf. | 70 | Black | ✓ | ✓ | CLASS III | ✓ | ✓ | ||

| S7000AB | VMQ | Perox. | 70 | Rust | ✓ | ✓ | CLASS IV | ✓ | ✓ | ✓ | |

| S7031AB | VMQ | Perox. | 70 | Rust | ✓ | ✓ | CLASS IV | ✓ | ✓ | ||

| V7092AP | FKM | Perox. | 70 | White | ✓ | ✓ | |||||

| V7692AA01 | FKM | Perox. | 75 | Black | ✓ | ✓ | CLASS I CLASS III |

✓ | ✓ | ✓ |

FDA 21 CFR 177.2600

(d) Rubber articles intended for use with dry food are so formulated and cured under conditions of good manufacturing practice as to be suitable for repeated use.

(e) Rubber articles intended for repeated use in contact with aqueous food shall meet the following specifications: The food-contact surface of the rubber article in the finished form in which it is to contact food, when extracted with distilled water at reflux temperature, shallyield total extractives not to exceed 20 milligrams per square inch during the first 7 hours of extraction, nor to exceed 1 milligram per square inch during the succeeding 2 hours of extraction.

(f) Rubber articles intended for repeated use in contact with fatty foods shall meet the following specifications: The food-contact surface of the rubber article in the finished form in which it is to contact food, when extracted with n-hexane at reflux temperature, shallyield total extractives not to exceed 175 milligrams per square inch during the first 7 hours of extraction, nor to exceed 4 milligrams per square inch during the succeeding 2 hours of extraction.

※For more GMORS material certifications, please visit the relevant page.

(Material Certified)